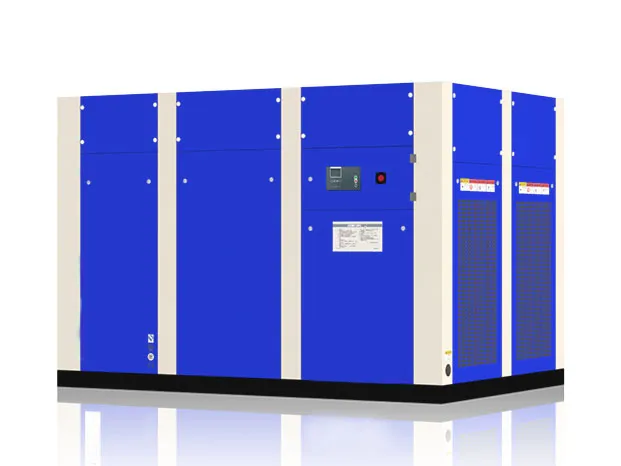

OIL FREE SCROLL

AIR COMPRESSOR

An oil-free scroll air compressor is an air compressor that does not use oil to lubricate its moving parts. This type of compressor is commonly used in applications where oil contamination cannot be accepted, such as food and beverage processing, medical applications, and pharmaceutical manufacturing.

Oil-free Scroll Air Compressors Advantages Over Oil-lubricated Air Compressors, Including:

Cleaner Air

They produce cleaner air. This is because there is no oil to contaminate the air.

More Efficient

They are more efficient. This is because there is no oil to lubricate the moving parts, which reduces friction and heat.

Quieter

They are quieter. This is because there are no moving parts in contact with each other, which reduces vibration.

Less Maintenance

They require less maintenance. This is because there is no oil to change or filters to clean.

Advantages of Oil-Free Scroll Air Compressors

- Compact and portable design

- Don’t require manual lubrication

- Easier to operate

- Suited for applications jeopardized by oil contamination

- Better for non-commercial purposes

Oil vs. Oil-Free Scroll Air Compressors

The most obvious disadvantage of using oil-lubricated compressors is the risk of oil contamination. Oils used to lubricate, seal, and cool machines leave a certain oil content in the compressed air that must be removed by separation or filtration. In industries where air purity is critical (especially in sterile environments), even the smallest droplets of oil are at risk of contamination.

The biggest argument against oil-free scroll air compressors is their relatively short life expectancy. Again, this may have been the case then, but the longevity of today’s oil-free compressors is no longer an issue.

Significant advances have been made in oil-free technology, allowing oil-free scroll air compressors to operate at lower temperatures and last longer. In addition, they require less maintenance than oil compressors.

When Choosing Oil-free Air Compressor, The Following Factors Need To Be Considered:

Air Amount

The amount of air you need. This is measured in cubic feet per minute (CFM).

The Duty Cycle

The duty cycle. This is the amount of time the compressor can run continuously without overheating.

Pressure

The pressure you need. This is measured in pounds per square inch (PSI).

Noise Level

The noise level. This is measured in decibels (dB).

- Medical

- Pharmaceutical

- Food & Beverage

- Life Science

- Chemical

- Power Generation

View All Services

How Do Oil-Free Scroll Air Compressors Work?

The primary purpose of oil-free scroll air compressors and oil-lubricated compressors is the same, but the amount of compressed air and the applications in which they will be used can make a significant difference.

Oil-powered air compressors are the best choice for construction and heavy industrial applications requiring power equipment. They can run for a long time and compress as much air as needed. If there is not any pressing need for lube free air compressors, such as when air pollution must be stopped, lube based compressors are a more cost-effective option.

No lubricating oil air compressor is lighter, make its become need mobility or less a great option for the application of compressed air, for example, in the healthcare industry.

Get In Touch!

We are one of the best oil-free scroll air compressor manufacturers.We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service.We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information and cooperate with us!

Call Us

+86 13083988828